- HEINZ AND TESCO HAVE TEAMED UP WITH EXPERTS IN RECYCLING TECHNOLOGY AND PACKAGING INDUSTRY LEADERS PLASTIC ENERGY, SABIC AND BERRY GLOBAL

- TOGETHER THE TEAM HAVE DEVELOPED A NEW MORE SUSTAINABLE PACKAGING SOLUTION USING ADVANCED RECYCLING

- INNOVATIVE NEW HEINZ BEANZ SNAP POTS ARE MADE WITH RECYCLED POST-CONSUMER SOFT PLASTICS COLLECTED AT TESCO STORES

Heinz and Tesco have embarked on a pioneering trial in partnership with experts that they hope will inspire the wider industry to take action in tackling the lack of soft plastic waste being recycled in the UK.

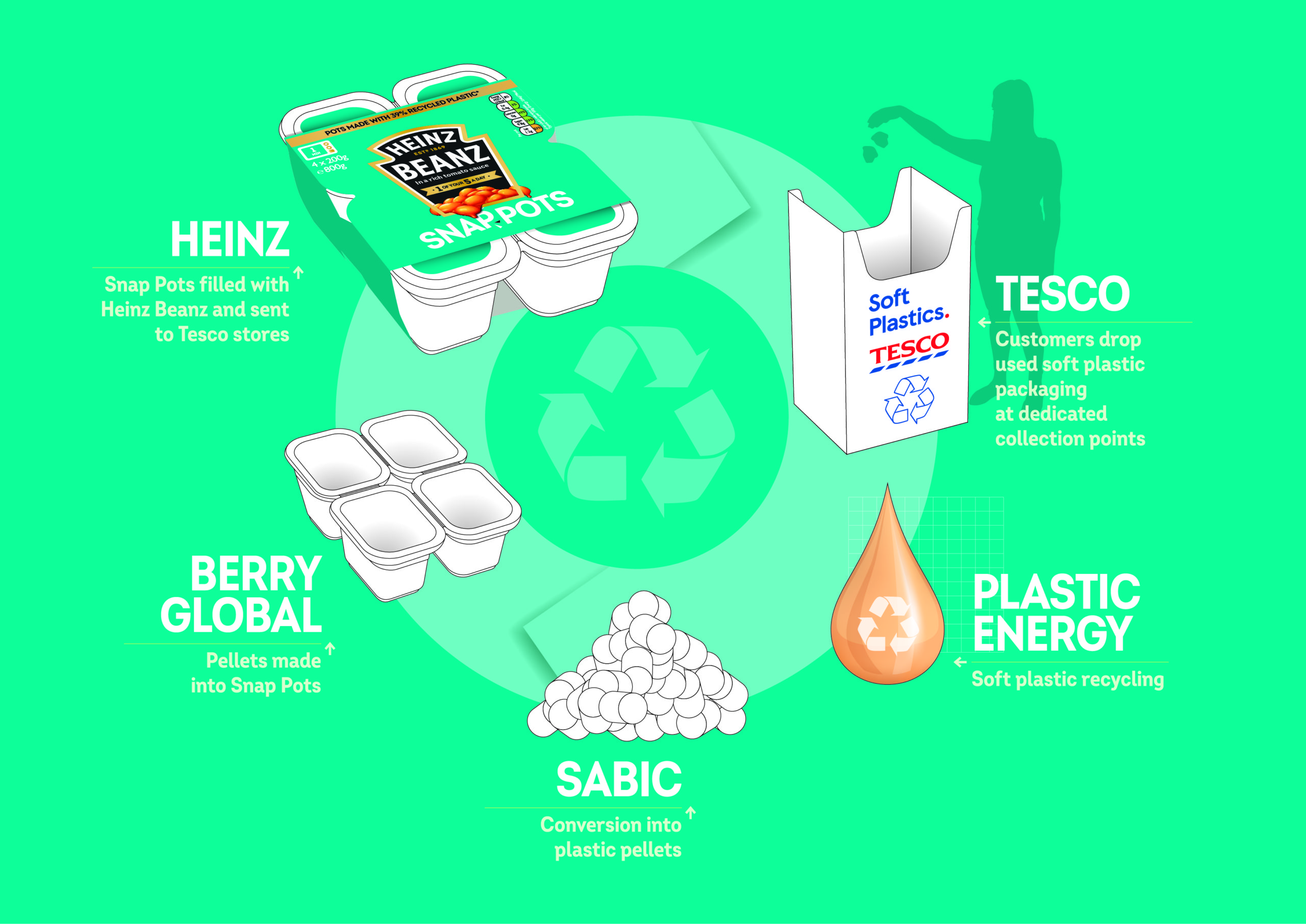

Heinz and its expert partners – Plastic Energy, SABIC and Berry Global – have developed new Heinz Beanz Snap Pots which are made from 39% recycled soft plastic, collected from customers at Tesco’s in-store collection points.

The new Heinz Beanz Snap Pots were designed and developed by Heinz’s R&D team to be more sustainable while retaining what makes them so popular with consumers: their convenience, handy snappable format, microwaveability and ability to ensure the product remains fresh. They’re produced through a collaborative 5-step process:

- Collect – Post-consumer soft plastic packaging which would otherwise be incinerated or taken to landfill is collected at Tesco stores nationwide

- Convert– The collected packaging is then delivered to Plastic Energy, a global leader in advanced recycling technology, where it is converted using their patented TAC process into an optimal oil feedstock

- Transform – SABIC takes the recycled oil and uses it as alternative feedstock in the production process to manufacture virgin, food-contact approved polymer pellets

- Create– On site at its ISCC-certified manufacturing sites, sustainable packaging specialist Berry Global then applies its thermoforming capabilities to mould the food-contact approved polymer pellets made with 39% recycled plastics based on a mass-balance approach into new, post-consumer recyclable Snap Pots

- Recycle – Finally, the completed Snap Pots are sent to Heinz to be filled with Beanz and delivered back to Tesco stores. Once used, the pots can be recycled as part of kerbside collections

The recycled plastic used in the snappable pots is certified by the ISCC, a global sustainability certification system that supports the transition to a circular economy. The 39% recycled plastic they contain was validated using the “mass balance approach” endorsed by ISCC, which makes it possible to track the amount and sustainability characteristics of materials used in the manufacturing process.

To date soft plastic packaging has been notoriously difficult to recycle, and until 2020 just six percent of UK soft plastics were being recycled[1]. Tesco started collecting soft plastic in all its large stores in 2021 to help plug this recycling gap in the UK. Once collected by Tesco, as much as possible is recycled into new products and packaging. From August, all materials will be sorted in the UK. The move to make soft plastics into food-grade, microwavable snappable pots that can be returned into the kerbside recycling loop is believed to be a world first.

Resources and Waste Minister Jo Churchill said: “It is great to see Heinz and Tesco working together to trial packaging to boost recycling levels. Businesses across the UK are stepping up to tackle plastic pollution and we want to incentivise them to do so. Through our landmark Environment Act, we are also making it easier for consumers to recycle more.”

Jojo de Noronha, President Northern Europe at Heinz, said: “We’re proud to have teamed up with leading experts to bring this important innovation to our customers. Our hope is that this prompts an industry-wide look at what more can be done to address the lack of soft plastics being recycled in the UK, and we can, as a collective, get better when it comes to developing new packaging solutions that are both good for both our consumers and for our planet.”

Carlos Monreal, CEO of Plastic Energy, said: “We are excited to partner with Heinz, Tesco, SABIC and Berry Global on this value-chain collaboration which paves the way for enhanced sustainability in packaging. Using Plastic Energy’s innovative advanced recycling technology, post-consumer plastic waste, which would otherwise be sent to landfill or incineration, can be converted into recycled oils, which are used as a replacement for fossil oils in the manufacturing of new plastics. This collaboration proves that through advanced recycling, more recycled plastic can be incorporated into packaging in the future, which benefits the circular economy.”

Lada Kurelec, General Manager PP, PET, PS, PVC, PU & Elastomers Businesses for Petrochemicals at SABIC, said: “We are happy to reaffirm our role as a provider of unique circular solutions. Beyond guidance in selecting the right material, we have brought value chain partners together and provided crucial elements such as support with certification processes or life-cycle assessment calculations, all while helping to prevent valuable used plastics from being lost to landfill or incineration.”

Jean-Marc Galvez, President of Berry Global’s Consumer Packaging International Division, said: “This is a prime example of an innovative advancement in circular packaging design made possible by collaboration across the entire value chain. This type of circular approach helps capture and reuse plastics that currently go unrecycled to keep materials in use and out of our oceans and landfills.”

Sarah Bradbury, Tesco’s Group Quality Director, said: “This innovative collaboration is one of the ways that soft plastic returned to stores by our customers will be recycled into new food-grade packaging. After doing everything we can to remove and reduce plastic, we want to develop circular recycling solutions like this so the materials we use stay in our packaging and out of the environment”.

This is the latest in a series of sustainable packaging innovations by Heinz, including the kerbside recyclable Heinz for Baby food pouch and the Heinz Eco-Friendly Sleeve on canned products, as the company continues its journey in supporting a circular economy. This packaging innovation is part of Heinz’s global pledge to aim to make 100% of its packaging recyclable, reusable or compostable by 2025.

[1] WRAP https://wrap.org.uk/resources/guide/creating-circular-economy-flexible-plastic-packaging#

###

For more information please contact:

emilie@wonderlandcomms.com, 07880 404 469

ellie@wonderlandcomms.com, 07595 667 729

jemma@wonderlandcomms.com, 07811 209 207

About Plastic Energy

Plastic Energy is a global leader in chemical recycling, offering a sustainable solution to help prevent plastic waste, transforming previously unrecyclable plastic waste into a valuable resource. Our patented and proven chemical recycling technology converts end-of-life plastic waste into an optimal feedstock (TACOIL) for making virgin-quality recycled plastics. Plastic Energy currently has two chemical recycling plants that are in constant operation in Spain and is one of the few companies worldwide that has sold TACOIL from the conversion of end-of-life plastic waste to replace fossil oils in the manufacturing of new plastics. We are leading our field in the transition to a low-carbon circular economy for plastics. Visit our website at plasticenergy.com and follow us on Twitter and Linkedin.

About SABIC

SABIC is a global diversified chemicals company, headquartered in Riyadh, Saudi Arabia. It manufactures on a global scale in the Americas, Europe, Middle East and Asia Pacific, making distinctly different kinds of products: chemicals, commodity and high performance plastics, agri-nutrients and metals.SABIC supports its customers by identifying and developing opportunities in key end-use applications such as construction, medical devices, packaging, agri-nutrients, electrical and electronics, transportation and clean energy.

SABIC’s production in 2021 stood at 58 million metric tons.The company has more than 31,000 employees worldwide and operates in around 50 countries. Fostering innovation and a spirit of ingenuity, SABIC has 10,090 patents and pending applications, and has significant research resources with innovation hubs in five key geographies – USA, Europe, Middle East, South Asia and North Asia. For more information visit our website or connect with us on LinkedIn or Twitter.

About Berry Global

At Berry Global Group; Inc. (NYSE: BERY); we create innovative packaging and engineered products that we believe make life better for people and the planet. We do this every day by leveraging our unmatched global capabilities; sustainability leadership; and deep innovation expertise to serve customers of all sizes around the world. Harnessing the strength in our diversity and industry-leading talent of 47,000 global employees across more than 300 locations; we partner with customers to develop; design; and manufacture innovative products with an eye toward the circular economy. The challenges we solve and the innovations we pioneer benefit our customers at every stage of their journey. For more information; visit our website; or connect with us on LinkedIn or Twitter.